Our Services

We provide top-notch automation engineering services.

At KSOFT ENGINNERING CONSULTANCY SERVICES, we specialize in cutting-edge PLC programming and seamless system integration solutions designed to optimize your industrial processes. Our expertise ensures that your systems work together flawlessly, enhancing efficiency and reliability.

Programmable Logic Controllers (PLCs) are digital computers designed for industrial automation and control. They are crucial for managing and automating processes in various industries.

System Integration involves connecting various subsystems into a cohesive and efficient whole. It ensures that different components of your industrial operations work together smoothly.

With years of experience in PLC programming and system integration, our team at KSOFT ENGINNERING CONSULTANCY SERVICES offers unparalleled expertise. We provide customized solutions tailored to your specific needs, ensuring optimal performance and reliability.

Ready to optimize your industrial processes? Contact us today to learn more about our PLC programming and system integration services.

At KSOFT Engineering Consultancy Services, we deliver tailored Ignition SCADA solutions designed to meet the unique needs of your industrial operations. As a certified Ignition credentialed integrator, we have the expertise to develop scalable systems that offer real-time monitoring, control, and advanced analytics, all from a single, centralized platform. Whether you’re managing a small facility or a large enterprise, we ensure seamless integration with your existing infrastructure, including PLCs, robots, drives, and other industrial equipment.

Our solutions empower industries such as automotive, manufacturing, and energy to enhance operational efficiency, improve decision-making, and maintain continuous control over complex processes. Our team of certified Ignition SCADA professionals is dedicated to delivering systems that not only meet your immediate needs but are also designed to scale as your business grows.

Contact us today to discover how our Ignition SCADA Development services can transform your industrial automation and drive your business forward.

At KSOFT ENGINEERING CONSULTANCY SERVICES, Welcome to our detailed Ignition demo project video! This presentation offers a thorough exploration of the Ignition platform, designed to showcase its capabilities and how it can significantly enhance your operational processes.

At KSOFT ENGINEERING CONSULTANCY SERVICES, Experience Ignition live through our real-time demonstration. This segment highlights how Ignition manages data acquisition, visualization, and control. Watch as we walk you through practical scenarios and showcase the platform’s efficiency in handling complex tasks.

Factory Acceptance Testing (FAT) is conducted at the manufacturer’s facility to verify that equipment or systems perform as expected before they are shipped to the customer site. FAT helps identify any issues early in the process, reducing the risk of costly modifications later on.

By providing comprehensive FAT support, you ensure that the systems you deliver are reliable, fully functional, and ready for deployment, which enhances customer satisfaction and operational efficiency.

Site Acceptance Testing (SAT): This is conducted at the final installation site to verify that the system performs as expected in its operational environment. It follows FAT (Factory Acceptance Testing) and ensures that all components work together correctly after installation.

Commissioning: This process involves the final setup, testing, and tuning of the system to ensure it operates according to the specifications and requirements. It includes verifying that the system is fully integrated, operational, and ready for production use.

By providing comprehensive SAT support and commissioning, you ensure that the system is fully operational, meets all requirements, and is ready for productive use, which enhances overall system performance and customer satisfaction.

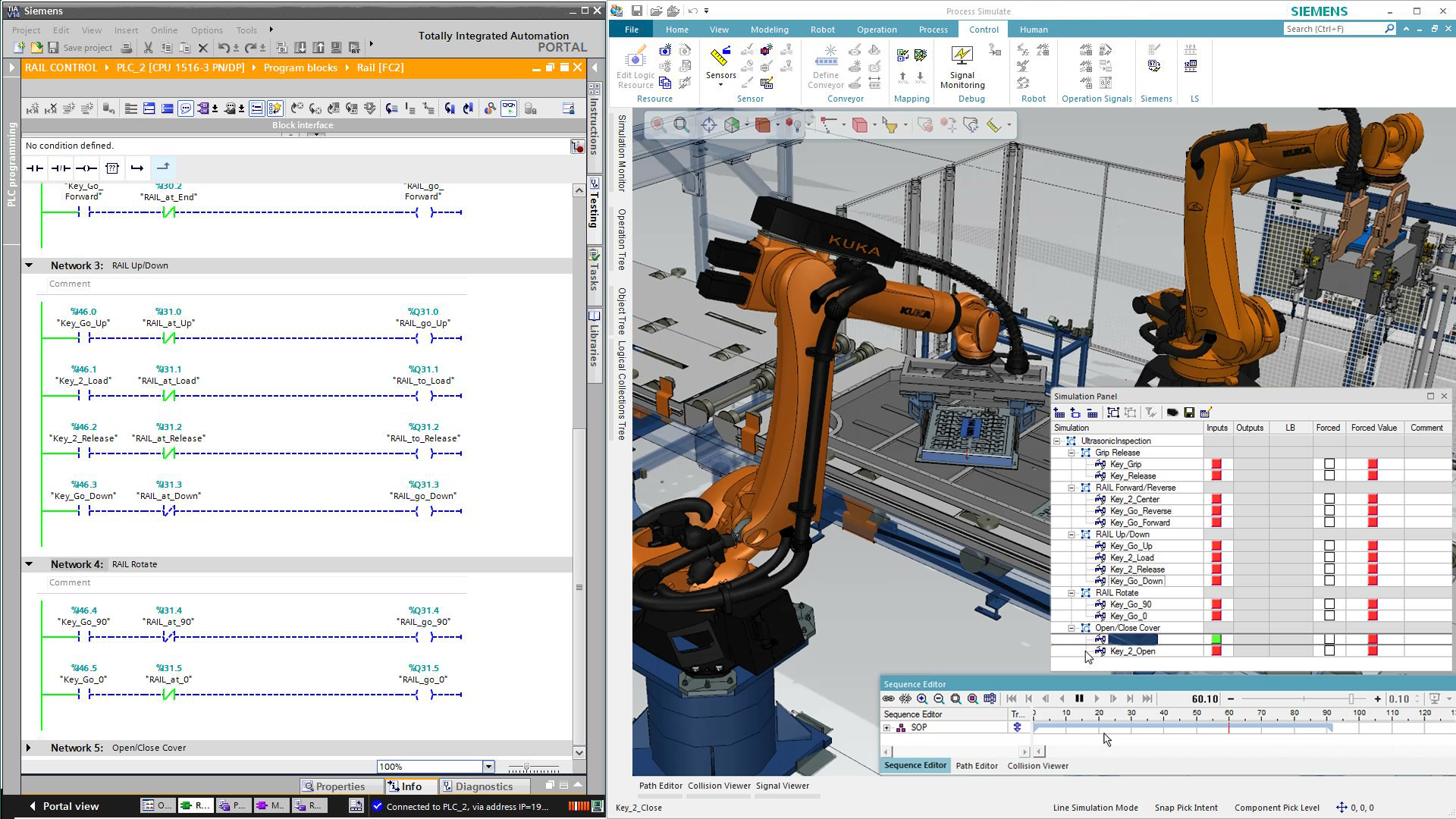

At KSOFT ENGINEERING CONSULTANCY SERVICES, we leverage the cutting-edge capabilities of Siemens' Technomatix Process Simulation software to revolutionize your manufacturing processes. Our expertise in process simulation allows us to model, analyze, and optimize your production systems with unparalleled accuracy and efficiency.

Transform your manufacturing processes with precision and confidence. Contact us today to learn how our expertise in Technomatix Process Simulation can drive your operational excellence and innovation.

At KSOFT ENGINEERING CONSULTANCY SERVICES, we leverage Siemens' Technomatix Process Simulation software to transform manufacturing processes and drive operational excellence. Our latest video provides an in-depth look at how we use advanced simulation technology to optimize your manufacturing operations.

n this video, we demonstrate how Technomatix Process Simulation enables us to model, analyze, and optimize complex manufacturing processes. From detailed virtual models to real-time performance analysis, see how our expertise helps enhance efficiency, reduce costs, and improve product quality

At KSOFT ENGINEERING CONSULTANCY SERVICES, we utilize Siemens' Technomatix Virtual Commissioning (VC) to redefine the way we validate and optimize your manufacturing processes. Our expertise in virtual commissioning enables us to simulate, test, and refine your control systems and automation setups in a virtual environment, ensuring optimal performance and seamless implementation.

Transform your manufacturing processes with precision and confidence. Contact us today to learn how our expertise in Technomatix Process Simulation can drive your operational excellence and innovation.

Discover how our virtual commissioning capabilities with Technomatix VC can transform your manufacturing processes.

Contact Us

Contact Us